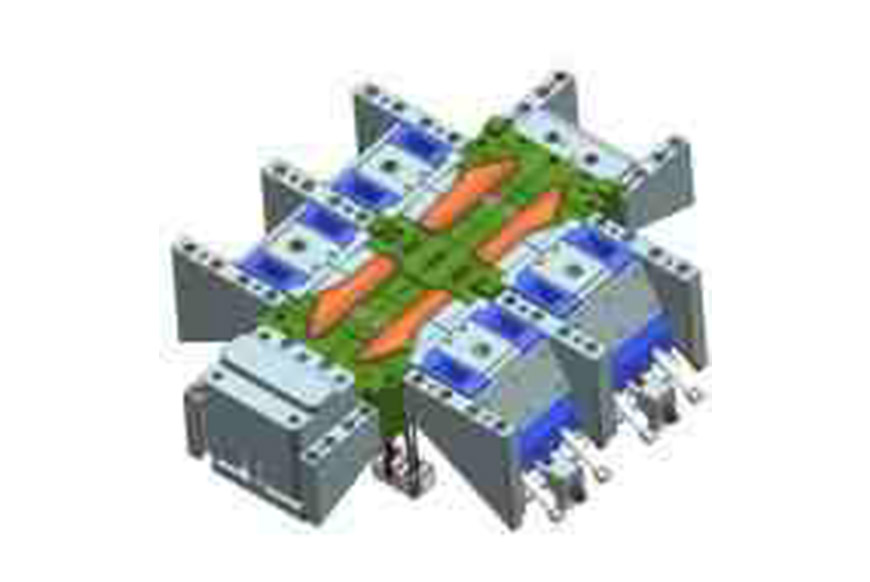

Our Design Department employs highly skilled Engineers capable of using the most advanced modelling software. Our NX CAD/CAM (formely Unigraphics) software enable us to machine the details of the tool directly from the design data. This not only reduces the lead time of mould parts manufacturing but the potential for human error is also greatly reduced. We accept file formats which include, UGII, Parasolids, and STEP files.

Design Profile:

- Engineering assistance for product design.

- Manufacturing feasibility assistance.

- Prototyping services.

- Mold flow & mold cooling analysis.

- Design optimization for enhanced mould life.

Within our Engineering Department, our professional staff of Design Engineers provide you innovative ideas you need to ensure your product’s success. With our NX CAD/CAM software, the integrity of your part data is maintained throughout the entire process. After creating a solid model of the mould, the cavity detail is machined with the latest technology CNC milling, WEDM and EDM machines. The moulded parts are then measured and compared to your original part file with our inspection instruments like, CMM, VMM etc.